See also Supported Industries

Services

Vendor Surveillance / Third Party Inspection

To ensure your purchased products are built to your quality standards and in accordance with your technical specifications, IQC offers vendor surveillance throughout the procurement process, from purchase to fabrication. This is done through on-site checks and comprehensive reporting, to ensure efficiency and product quality.

To ensure your purchased products are built to your quality standards and in accordance with your technical specifications, IQC offers vendor surveillance throughout the procurement process, from purchase to fabrication. This is done through on-site checks and comprehensive reporting, to ensure efficiency and product quality.

We provide quality inspections by hiring the most experienced and qualified inspectors available. All inspectors are interviewed and screened for practical expertise, hands-on experience, technical knowledge, communication and interpersonal skills. We will make every effort to match your needs to the strengths and skills of our individual inspectors.

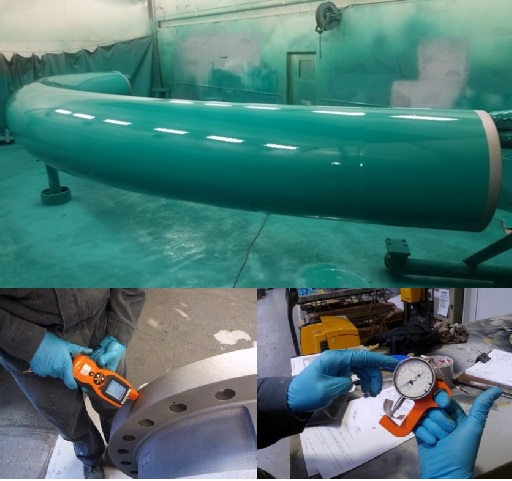

Coating Inspection

To ensure the safety of your product and piping equipment, we offer coating inspections by Level I, II and III (peer review) Coating Inspection Technicians certified by the National Association of Corrosion Engineers (NACE).

To ensure the safety of your product and piping equipment, we offer coating inspections by Level I, II and III (peer review) Coating Inspection Technicians certified by the National Association of Corrosion Engineers (NACE).

Inspections can be done in-process or after application, for new equipment or repairs, and may evaluate:

- Effectiveness against corrosion

- Performance in changing conditions and environments

- Coating Application

- Failures

We are capable of developing an inspection and test plan (ITP) specific to your project, or you may provide an ITP and we will accommodate your specifications.

Nondestructive Testing

Our nondestructive testing (NDT) services are available for new fabrications or repairs of pressure vessels, pressure piping, boilers and structural steel. External and/or internal testing is available and will be completed by CGSB certified technicians and engineering support.

Our nondestructive testing (NDT) services are available for new fabrications or repairs of pressure vessels, pressure piping, boilers and structural steel. External and/or internal testing is available and will be completed by CGSB certified technicians and engineering support.

We offer excellent service in performing:

- Ultrasonic Inspections

- Magnetic Particle Inspections

- Liquid Penetrant Inspections

- Visual examinations

Fixed Anchor Linear Load Testing

IQC has portable testing equipment designed for establishing linear loading of mechanical and resin anchors, eye type anchors, threaded bar, re-bar and structural bolts and fixings. We currently have two units, of different sizes,which can be utilized based on the application. The larger test assembly will pull with direct tension up to 145 kN. These testers are highly effective at determining whether post-applied anchor bolts have been installed correctly, BEFORE they are structurally loaded.

Expediting Services

In order to meet your deadlines and maintain smooth workflow, it is essential that your purchased equipment be delivered on time. IQC's personnel are skilled at expediting and can help you avoid costly delays by:

In order to meet your deadlines and maintain smooth workflow, it is essential that your purchased equipment be delivered on time. IQC's personnel are skilled at expediting and can help you avoid costly delays by:

- Acquiring necessary information

- Interpreting scheduling systems

- Understanding your production processes

- Effectively communicating with your vendor and customer contacts

Quality Audit Program

IQC auditors are available to conduct comprehensive Quality Assurance Audits of your vendor's performance capabilities. Our audits can ensure your vendor's quality programs meet your standards, and may encompass:

- Quality Assurance procedures

- Safety

- Materials procurement and traceability

- Inspection procedures

- Equipment

- Quality of workmanship

At your request, additional areas of vendor performance may also be included in our audits.

Metallurgical Engineering

IQC offers a full range of consulting and metallurgical engineering services, such as metals testing and metals-related inspections.

IQC offers a full range of consulting and metallurgical engineering services, such as metals testing and metals-related inspections.

Consulting Services

Quality Assurance Programs developed by IQC are created to suit your unique requirements, and can be created to comply with Canadian and International standards such as CSA and ISO.

Inspection and Test Plans are crucial in ensuring your products are compliant with your specifications, and need to be provided to your supplier prior to manufacturing or fabrication. IQC develops these plans to incorporate your requirements in a clear, concise document.

Project Services

For special projects, IQC can provide staff to supplement your existing Quality Assurance and/or Inspection team. Our staff can work on-site at your facility / job site, or off-site at our offices.

For special projects, IQC can provide staff to supplement your existing Quality Assurance and/or Inspection team. Our staff can work on-site at your facility / job site, or off-site at our offices.